Anti-Static Brushes and Static Electricity

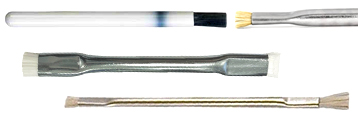

Static charge (electricity) is a fairly simple, but often misunderstood event. Briefly stated, a static charge is generated between materials through friction, pressure or separation of two materials. This process is called the Triboelectric Effect [tribo means rubbing]. A material that inhibits the generation of static charges is classified as low charging (anti-static). Low charging (anti-static) materials used to make these natural fill brushes include Wood, Hog Bristle, Horse Hair and Goat Hair. These materials can be used in ESD sensitive areas as long as the brush remains in a liquid environment. In a dry environment, only conductive or dissipative materials should be used in ESD safe areas. Browse our ESD safe brushes today!

Not sure which anti-static ESD brush you need for your business?

Our customer service representatives can answer your questions. Call us at: 1-800-950-7950 or 1-323-724-7777

An antistatic brush is a brush made using “low charging” fill material. Low Charging brushes are used for applications where the inhibition of charges >200v is desirable, as there is a possible static charge generation of <200v during use. The most common antistatic materials used to make these industrial cleaning tools include wood, hog bristle, horsehair and goat hair. Less common materials such as static dissipative Nylon and static dissipative acetal are also anti-static. In a liquid environment, these types of industrial brushes can be safely used in ESD sensitive areas without any issues. In many industries, such as in the electronics and cleanroom industries, it is imperative to use this category of brush to avoid hazardous incidents. Don’t worry, Gordon Brush® has the perfect anti-static and static electricity brushes for your particular needs that meet ESD standards and come with customer satisfaction guaranteed.

As the official EIA and the ESD Associations define, antistatic materials refer to the property of material that inhibits triboelectric generation of static charges (usually less than 200 volts). Materials such as cotton are close to “neutral”, or as centered as possible on the triboelectric series to be formally defined as “antistatic.” It is important to note that a brush’s fill material antistatic characteristics do not necessarily correlate with its resistivity level. Since some job applications utilizing brushes call for a confirmation on the anti-static intensities due to the nature or safety of the workspace, it is essential to know exactly what you’re getting. Gordon Brush® carefully selects the fill and handle materials on all our products, including our low charging ESD safe type brushes, so you know you can trust our products.

Due to the risk of static charge adversely affecting your project, our brush experts encourage all customers to enquire about the correct type of low static or anti-static brush, they need if they aren’t 100% sure. The types of anti-static brushes include: conductive, static dissipative and low charging and can vary within those categories depending on the materials used. Be sure to reach out to our American brush manufacturing team for assistance on these types of brushes or for special custom orders as well. We are here to make your orders simpler! Gordon Brush® is your number one online resource for industrial brushes for a reason. Shop today and see why!

If a brush exists, we have it…if it doesn't, we'll make it!

Block Brushes

Block Brushes Bore Brushes

Bore Brushes Cup Brushes

Cup Brushes Cylinder Brushes

Cylinder Brushes Disk Brushes

Disk Brushes Flow Thru Brushes

Flow Thru Brushes Hand Held Brushes

Hand Held Brushes Inward & Outward Disk Brushes

Inward & Outward Disk Brushes Inward Wound Coil Brushes

Inward Wound Coil Brushes Outward Wound Coil Brushes

Outward Wound Coil Brushes Pencil & Applicator Brushes

Pencil & Applicator Brushes Straight Strip Brushes

Straight Strip Brushes Twisted-In-Wire Brushes

Twisted-In-Wire Brushes Natural Fill Brushes

Natural Fill Brushes Wire Fill Brushes

Wire Fill Brushes Synthetic Fill Brushes

Synthetic Fill Brushes Metal Handle Brushes

Metal Handle Brushes Plastic Handle Brushes

Plastic Handle Brushes Wood Handle Brushes

Wood Handle Brushes