View All Related Products

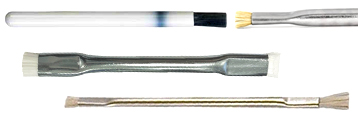

Abrasive spiral power brushes are made with galvanized steel wire, and come with either a single spiral or double-stem, filled with Silicon Carbide abrasive Nylon or Aluminum Oxide abrasive Nylon. These materials provide for a high degree of stiffness, a fast cutting rate, and can be used for both wet and dry applications, manually or in power tools.

Single spiral, double stem brushes use one layer of filament twisted between double stem wires for added strength. It is always important to operate a spiral brush in the same direction as the twist in the stem because rotating the brush in the opposite direction may loosen the stem wire and cause it to separate and come apart.

Brush lengths range from 1-1/2" to 2", with overall lengths ranging between 4" to 5-1/2", and brush diameters from ¼" to 2".

These durable, abrasive spiral power brushes come in a choice of abrasive Nylon fill materials where the Nylon has been impregnated with an abrasive mineral such as silicon carbide or aluminum oxide. The sides of the Nylon filament act as flexible files to reach surfaces where wire bristles might not be as effective. Silicon carbide grit is coarse and acid resistant, with a range from 80 to 320, whereas aluminum oxide is much finer having a grit of 600. Silicon carbide grit adds hardness to the Nylon filaments having a Mohs value between 9 and 10. Gritted aluminum oxide is a very popular abrasive choice being both fracture-resistant and strong.

The wire stems are made of galvanized steel. Galvanized steel has superior resistance to heat, rust and corrosion and is excellent for both wet and dry applications. Galvanized steel is coated with a thin layer of zinc that helps guard against corrosion and unwanted damage through chlorine exposure.

Selecting the correct size of brush for an application can be challenging, when multiple specifications need to be met. Gordon Brush® has addressed this need with its state-of-the-art Wizard feature. By using the Wizard, a customer can search for multiple detailed specifications simultaneously to find the exact brush needed.

If you do not find the exact brush to meet your specific needs within our extensive inventory, please contact Gordon Brush® today for your custom brush manufacturing needs such as scratch and plater brushes , bore brushes , abrasive nylon cylinder brushes and more! If we are not already manufacturing a brush to fit your needs, our experienced engineers can custom design, custom make or modify a brush to meet your precise specifications. Whether you need a stock brush or custom made inudstrial cleaning brush, you can count on Gordon Brush® for the best brush ideas in America.

Call: 323 724-7777 , 800 950-7950 or Email: sales@GordonBrush.com

If a brush exists, we have it... if it doesn’t, we'll make it!

Block Brushes

Block Brushes Bore Brushes

Bore Brushes Cup Brushes

Cup Brushes Cylinder Brushes

Cylinder Brushes Disk Brushes

Disk Brushes Flow Thru Brushes

Flow Thru Brushes Hand Held Brushes

Hand Held Brushes Inward & Outward Disk Brushes

Inward & Outward Disk Brushes Inward Wound Coil Brushes

Inward Wound Coil Brushes Outward Wound Coil Brushes

Outward Wound Coil Brushes Pencil & Applicator Brushes

Pencil & Applicator Brushes Straight Strip Brushes

Straight Strip Brushes Twisted-In-Wire Brushes

Twisted-In-Wire Brushes Natural Fill Brushes

Natural Fill Brushes Wire Fill Brushes

Wire Fill Brushes Synthetic Fill Brushes

Synthetic Fill Brushes Metal Handle Brushes

Metal Handle Brushes Plastic Handle Brushes

Plastic Handle Brushes Wood Handle Brushes

Wood Handle Brushes